_01.png?crc=4174553115)

Cover Story

Research

People

Books

Archive

Download PDF

Download PDF

E-book version

Teaching

and Learning

Knowledge

Exchange

Liquid-repellent surfaces or coatings have myriad uses – from water-repellent clothing through self-cleaning buildings to friction-reducing surfaces for ships – but until recently the technology was either too expensive to produce, too unstable or simply not robust enough. Bio-inspiration is the key to the engineering team’s liquid-repellent breakthrough – material that is robust, versatile and cheap to produce. The technology has also just won the TechConnect Global Innovation Award for 2018.

Professor Rick Wang Liqiu and his team from the Department of Mechanical Engineering turned for inspiration to the springtail – an arthropod whose habitat is wet soil which is frequently flooded. Arthropods are invertebrates with an exoskeleton, segmented body and paired joint appendages and include insects, arachnids and crustaceans in their number. The springtail has adapted to its environment by evolving cuticles capable of repelling liquids and with high mechanical durability to resist friction from soil particles.

The porous surface the team designed is composed of honeycomb-shaped micro-cavities that are interconnected thereby ensuring stability, and which have a re-entrant structure which in turn ensures highly effective liquid repellency.

Professor Wang said: “The robust liquid-repellent structure is 21-times more mechanically stable than similar surfaces. The key to the technology is the unique design of the liquid-repellent structures and the microfluidic-droplets-based fabrication. The former resolves effectively the conflict between liquid repellency and mechanical stability, while the latter offers low-cost and scalable production of well-defined structures with precision and controllability.”

Oil and water

Comparing the new product to existing ones, Professor Wang said: “Other technologies can repel oil or water, ours is capable of repelling both. In fact, our liquid-repellent structures can repel at least 10 types of liquids, including surfactant solutions and organic solvents, as well as oil and water.

“Other technologies use chemistry to make the repellent, ours uses physical structure to repel liquids and is therefore more environmentally-friendly. Some other technologies have used physical structure as the repellent too, but they are structurally weak, while ours is stable. And finally, while others are expensive to produce, ours is commercially viable as we can produce it on a large scale at low cost.”

The cost for one square metre of material made with this technology is approximately HK$1, and the team has already signed an agreement with a major international company which intends to use it to make clothing.

“We also have a deal pending with another international company which will use it for coating electronic devices such as mobile phones,” said Professor Wang. “Currently the coating they use is chemical and not enviro-friendly. Ours has no environmentally-unfriendly elements in it.”

The technology has several applications for clothing. As well as the obvious advantages for rainwear, it also means that clothes will have to be washed less often, which has implications for the environment as it reduces power usage. It can also be used on kitchenware, making kitchen surfaces easier to keep clean and cookware much easier to wash, and windows which will need to be washed far less frequently.

There are lots of potential uses for transport too – water-repellent surfaces drastically reduce the drag on water vehicles, enabling cargo ships to move faster and saving on energy consumption. Liquid friction drag contributes to 60 to 70 per cent of the total drag for large cargo ships and 90 per cent for underwater vehicles.

At present Professor Wang and his team are doing further work on underwater applications, such as military submersibles. “Liquid-repellent surfaces reduce the friction drag by creating an effective slip boundary enabling the ship to move faster and use less fuel,” he said. “We are also looking into further uses for the product in fields ranging from automobiles, chemical engineering and electronics to biomedical industry and advanced manufacturing.”

A soil-dwelling springtail with dew (body length: approximately 2.5mm).

(Courtesy of Brian Valentine)

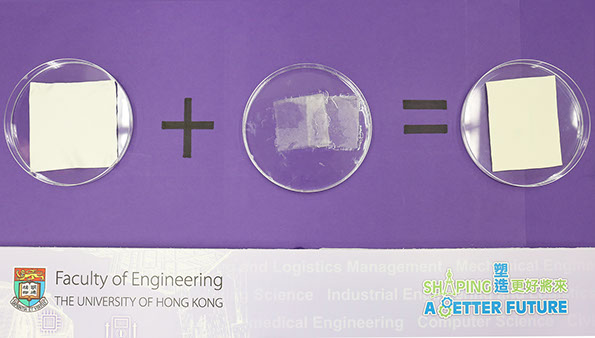

A piece of ordinary cloth (left) can become liquid-repellent (right) simply with a layer of porous surface material (middle).

Mother Nature provides key to staying dry

When refining liquid-repellent surface technology, a team of mechanical engineers was

bio-inspired.

![]() Our liquid-repellent structures can repel at least 10 types of liquids, including surfactant solutions and organic solvents, as well as oil and water.

Our liquid-repellent structures can repel at least 10 types of liquids, including surfactant solutions and organic solvents, as well as oil and water. ![]()

Professor Rick Wang Liqiu

Back

Next

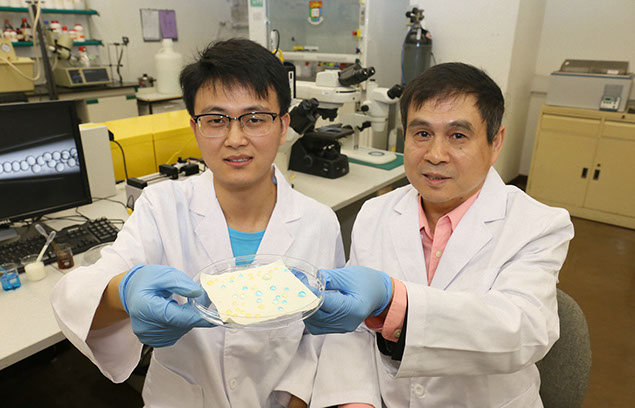

Professor Rick Wang Liqiu (right) and Dr Zhu Pingan (left) from the Department of Mechanical Engineering showcase the liquid-repellent material they innovated.

_12.png?crc=3961914953)